Frontier Industrial Composting Principles

COMPOSTING IS BACTERIA FARMING

The better you farm the higher quality the finished product!

It is not mysticism and there are no shortcuts, there is only MANAGEMENT and the RIGHT EQUIPMENT. Simply stated, composting is a matter of making the indigenous aerobic bacteria and fungi very happy. Kept at their optimum conditions – plenty to eat, good room temperature, and lots and lots of fresh air – they will perform their natural work – making quality compost, in record time without odors. Odors are the signal that the beneficial bacteria are not happy.

The purpose behind every Frontier Windrow Turner is to create the most favorable conditions possible for the microbes in every windrow you have. The design accomplishes the dynamics that need to happen inside each windrow.

This dynamic is neither an add-on idea nor a modification of other turning techniques, but rather it was incorporated as a fundamental principle into the heart of every turner since first machine. (First prototype notwithstanding)

WINDROW DYNAMICS

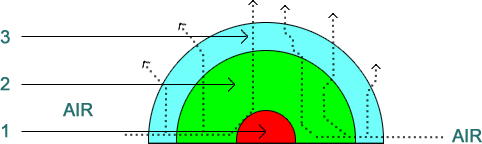

The following cross sectional drawing illustrates the concept of Windrow Dynamics for all of us laymen. It is not designed to be a technical presentation. Windrow Dynamics is the natural or unassisted airflow and subsequent bacterial activity of an undisturbed windrow caused by the rising of heated air.

In the above illustration, Zone # 1 represents what I call the Dead Zone, Odor Zone or the Anaerobic Zone that begins to form immediately in a new windrow. Zone # 2, which is the most active zone, is the hottest and has the most biological activity. This Zone is the ideal zone. It can be the “Sweet Spot” of composting. Left unattended this Zone will become too hot and begin to destroy beneficial bacteria or run out of fresh air and go cold/dead. Zone # 3 is the least compact zone in the entire row. It is cooler than Zone #2 but warmer than Zone #1. Bacterial activity in this Zone slows down rapidly as the moisture evaporates and cool air penetrates it.

FORMING OF THE ZONES

In new windrows, Zone # 1 (the dead zone) will begin to form im¬mediately and rapidly increase in size. The little Oxygen that exists is quickly consumed, and the relatively high moisture content of the material begins to settle there.

Zone # 2 is indefinable yet but begins to form because of the activity of Zone # 3, which remains small but active. If the row is not thoroughly mixed and aerated, Zone #3 will die and Zone #2 will become Zone # 1. The material is now anaerobic, (not enough oxygen to support aerobic bacteria).

Timing is everything, to prevent the anaerobic odors from causing problems and degrading the quality, complete mixing and aeration must begin before it reaches this stage. The natural dynamics will again reform the three Zones, but this time it will take a little longer to degrade. Each subsequent and timely turn of the windrow will slow down the formation of the Zones until the compost has reached an overall uniform finished valuable product.

The only effective manipulation of the material must include all four of the following actions.

- MIXING: There must be a complete shuffling or mixing of both the material and the newly formed bacterial colonies.

- AERATION: The CO2 must be removed. Since it is heavier than air, it must be forced out and away by fresh air.

- REFORMATION: The material must be allowed to reform in the row without squeezing.

- CONSISTENCY: Every portion of the windrow will have the same bacterial action and material composition.

Every Frontier Windrow Turner is capable of doing all the above in a thorough and uniform manner.

100% MIXING, Right to Left, Left to Right, Center in both directions (inside out), Bottom to Top and Top to Bottom.

Benefits:

- Vast reduction of odors caused by:

- Anaerobic pockets due to excess moisture collection.

- Anaerobic pockets due to lack of oxygen.

- Anaerobic pockets found in old clumps when they are finally broken open.

- Substantially increase the uniformity of working organisms in material.

- More material exposed to the same biological activity.

- The finished product is consistent and has no “mystery” clumps.

- Results are a higher real value of finished product

- Percentage of “overs” is vastly reduced

BREATHING (Aeration)

Aeration is not “agitation,” rather the active forcing of fresh air into every space in the windrow. It is much more than merely exposing the material to the ambient air inside the tunnel. The ambient air in the tunnel is full of CO2 released from the disturbed windrow. Unless fresh air is pumped into the tunnel, very little precious Oxygen will be available for the suffocating microbes, much like breathing into a paper bag. The essence of successful turning/aeration is to force (and retain) fresh breathable air into all the material while completely “disrupting,” “reshaping” and “restacking” the row.

REFORMATION

The thoroughly mixed and aerated material must be allowed to reshape the windrow without the squeezing by the turner shape. Frontier accomplishes this with special paddle design and placement. The fresh air placed into the material during the turning operation can easily be squeezed out defeating the whole purpose of aeration. All the material in the newly reformed windrow will begin the beneficial work of aerobically composting the material.

CONSISTENCY

When a baker is baking a cake from scratch he does not simply add all the material in a bowl and stir it with a fork for a few seconds then expect the cake to turn out good. His primary purpose for stirring is to THOROUGHLY mix all the ingredients, eliminate chunks, and insure consistency. The quality of the finished product, the cake, will be determined by both the ingredients and how well they are blended. No matter how you cut it, being able to produce consistent, mature compost with little or no odors does not happen by accident. It is the result of good management and equipment designed properly for the job. Only one windrow turner available today that can do all of this, the rugged and durable Frontier Windrow Turner utilizing the patented TURBORATOR™.

A WINDROW IS NOT A RACETRACK

Densely packed material can weigh twice as much as loose material and will require more power to turn. Frontier’s patented mixing and aeration system has been used extensively in bio-remediation of hard-packed oil contaminated clay soils with excellent results. Farming microbes in this type of material far exceeds the demands you will meet in an average compost site. Seeing a windrow of hard-packed clay turned into a fluffy and uniform material by a Frontier Turner is an amazing experience for the skeptic. This same system is built into each and every Frontier Windrow Turner from the Mighty Mike to the largest Self-propelled unit made.

Specially shaped “paddles” in the Frontier system literally turns the windrow inside out, outside in and upside down. Simultaneously these paddles blow a tremendous amount of air literally entraining the material for several feet behind the drum. The paddle design and the shape of the tunnel allows the turned material to form the windrow as it falls, thus maintaining the much-needed fluff (porosity) of the material. C02 is exchanged for oxygen in the process and the looseness of the material allows for continued convective “breathing” for several days.

Increasing forward speed without increasing horsepower requires a drum system that does less work. Rototiller type tines, long knifelike projections or auger style drums do less work, but they all will increase forward speed. Less work means faster forward speed or less horsepower to maintain the same speed of the Frontier. The less mixing and aerating that takes place during the turning process the less bacterial action generated, thus the longer it will take to finish the material. In a nutshell, it takes a certain amount of mixing, aerating, and fluffing to make finished compost. The more you can accomplish in one turn, the fewer turns needed. Sacrificing this action to gain speed of a single turn necessitates more turns and compromises material quality. The question should not be “How quickly can I turn a windrow?”, but rather:

- “How quickly can finished material be removed from the site?”

- “How good is the material?”

- “How much money am I leaving on the table by producing an inferior product?”

- “How much more profit can I make by cycling more material on my site in one year?”

Dairyman: How did you turn all those windrows so fast?

Helper: I took the drum out of the turner.